Sewer rehabilitation applications

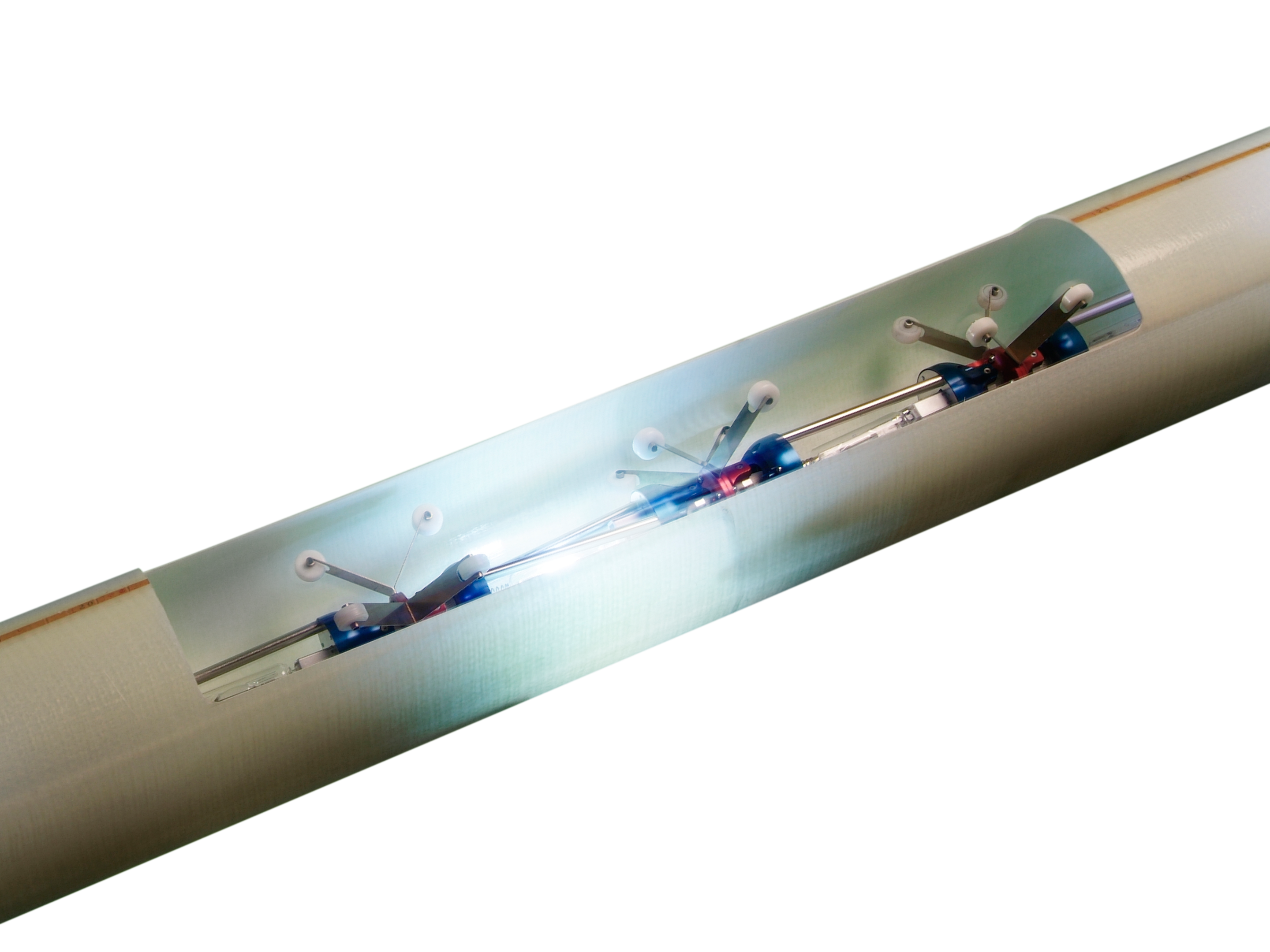

With inliner sewer rehabilitation, a method has been developed to repair damaged or leaking sewer pipes without exposing and replacing the pipe system. This results in a high potential for cost and time reduction in contrast to the conventional ripping method. The resin-impregnated pipe liners, which are inserted into the sewers, then inflated and cured, are made of glass fiber reinforced plastics (GRP). GRP is used wherever industrial materials are required to have maximum stability, outstanding chemical resistance and extreme durability.

With inliner sewer rehabilitation, a method has been developed to repair damaged or leaking sewer pipes without exposing and replacing the pipe system. This results in a high potential for cost and time reduction in contrast to the conventional ripping method. The resin-impregnated pipe liners, which are inserted into the sewers, then inflated and cured, are made of glass fiber reinforced plastics (GRP). GRP is used wherever industrial materials are required to have maximum stability, outstanding chemical resistance and extreme durability.

Canal renovation

With inliner sewer rehabilitation, a method has been developed to repair damaged or leaking sewer pipes without exposing and replacing the pipe system. This results in a high potential for cost and time reduction in contrast to the conventional ripping method. The resin-impregnated pipe liners, which are inserted into the sewers, then inflated and cured, are made of glass fiber reinforced plastics (GRP). GRP is used wherever industrial materials are required to have maximum stability, outstanding chemical resistance and extreme durability.