Woven fabrics

Roving fabric

GSO MultiFibre®

Commission weaving services

Roving fabric

Properties

Thermoset Application for e.g. reinforcing unsaturated polyester, epoxy and vinyl ester resins

Thermoplastic Application for e.g. reinforcing polypropylene and polyamide

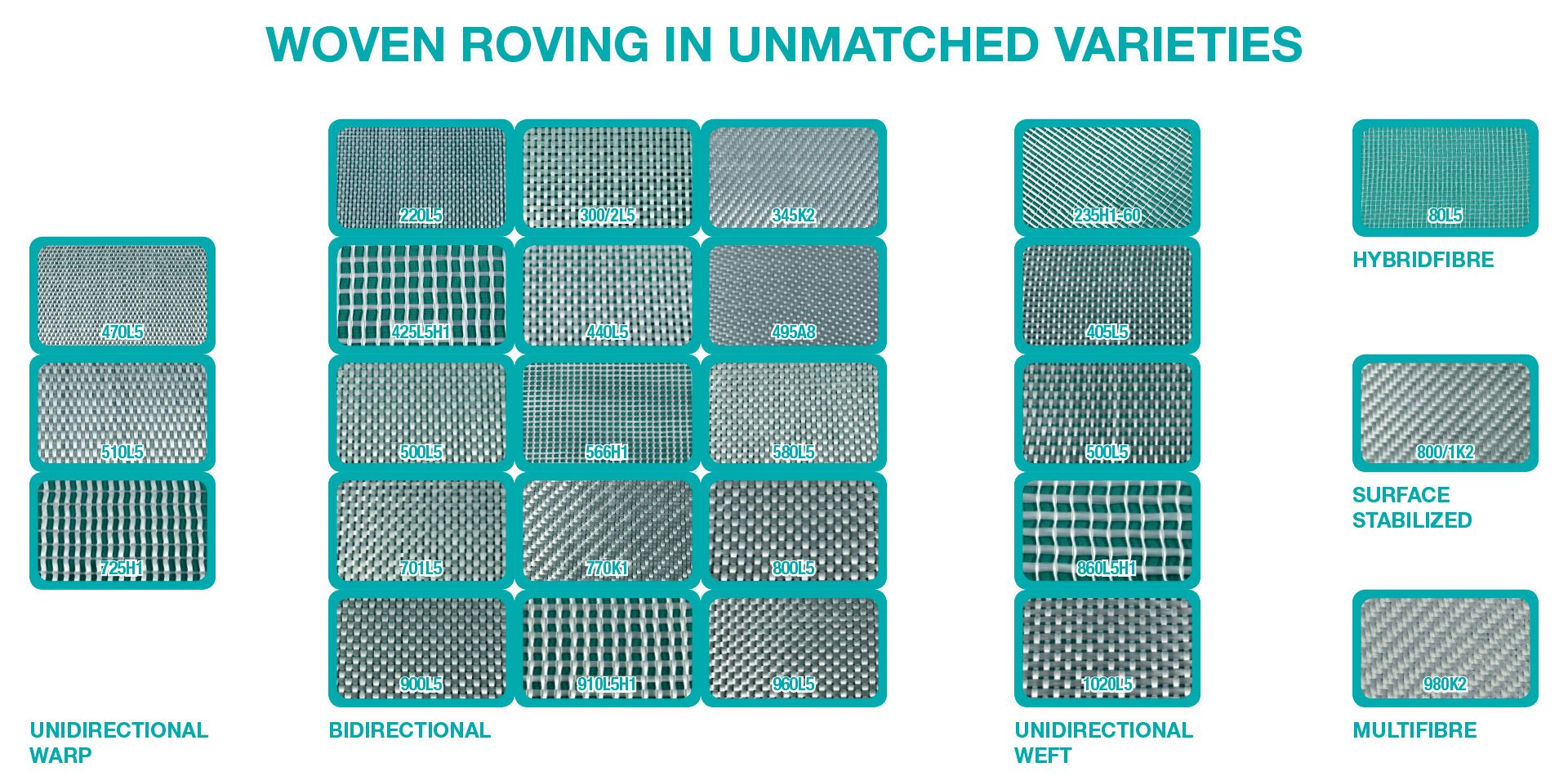

Bidirectional basis weight orientation (balanced basis weight proportion in warp and weft)

Unidirectional basis weight orientation (weft-reinforced or warp-reinforced)

Various basis weights from 100 g/m² to 2000 g/m²

A wide variety of binding types can be realized

Raw material widths from 100 to 410 cm

Cuts from 10 to 100 cm

Cut or uncut, solid or reinforced selvedge

Customized roll lengths

Markets

Tank and pipeline construction

Automotive

Sports and leisure

Boat building

Vehicle and lightweight construction

Your contact request

By sending your message, you agree to the processing of your data in accordance with our privacy policy. You can revoke this consent at any time.

| THERMOSET APPLICATIONS | ||||

|---|---|---|---|---|

| PREVIEW | GEWEBETYPE |

THREAD (tex)

CHAIN

|

SHOT

| SURFACE DIMENSIONS g/m² |

| |

GW 123-220 L5 | 320 | 320 | 220 |

| |

GW 123-300/2 L5 | 600 | 600 | 300 |

| |

GW 123-345 K2 | 320 | 320 | 345 |

| |

GW 123-425 L5H1 | 2400 | 2400 | 425 |

| |

GW 123-440 L5 | 1200 | 1200 | 440 |

| |

GW 123-580 L5 | 1200 | 1200 | 580 |

| |

GW 123-701 L5

|

2400 | 1200 | 701 |

| |

GW 123-770 K1 | 1200 | 1200 | 770 |

| |

GW 123-800 L5 | 2400 | 2400 | 800 |

| |

GW 123-900 L5 | 2400 | 2400 | 900 |

| |

GW 123-910 L5H1 | 4800 | 4800 | 910 |

| |

GW 123-960 L5 | 2400 | 2400 | 960 |

| BIDIRECTIONAL | ||||

| |

GW 223-470 L5 | 600 | 280 | 470 |

| |

GW 223-725 H1 | 4800 | 900 | 725 |

| UNIDIRECTIONAL CHAIN | ||||

| |

GW° 323-235 H1-60 | 68 | 1200 | 235 |

| |

GW 323-860 L5H1 | 2400 | 9600 | 860 |

| |

GWR 323-1020 L5 | 2400 | 4800 | 1020 |

| UNIDIRECTIONAL SHOT | ||||

| THERMOPLASTIC APPLICATIONS | ||||

|---|---|---|---|---|

| PREVIEW | WEAVING TYPE | THREAD (tex) CHAIN | WEFT | SURFACE DIMENSION g/m² |

| |

GW 173-600K2 | 1200 | 1200 | 600 |

| |

GW 176-600K2 | 1200 | 1200 | 600 |

| THERMOSET APPLICATIONS | |||

|---|---|---|---|

| TYPE OF BINDING | TYPE OF BINDING | SURFACE DIMENSIONS g/m² | |

| GW 123-220 L5 | Good dimensional stability / identical fabric sides | 220 | |

| |

GW 123-300/2 L5 | Good dimensional stability / identical fabric sides | 300 |

| |

GW 123-345 K2 | good drapability / identical fabric sides | 345 |

| |

GW 123-425 L5H1 | Grid structure / identical product sides | 425 |

| |

GW 123-440 L5 | Good dimensional stability / identical fabric sides | 440 |

| |

GW 123-495 A8 | Very good drapability / different fabric sides | 495 |

| |

GW 123-500 L5 | Good dimensional stability / identical fabric sides | 500 |

| |

GW 123-566 H1 | Grid structure / different fabric sides | 566 |

| |

GW 123-580 L5 | Good dimensional stability / identical fabric sides | 580 |

| |

GW 123-701 L5

|

Good dimensional stability / identical fabric sides | 701 |

| |

GW 123-770 K1 | good drapability / different fabric sides | 770 |

| |

GW 123-800 L5 | Good dimensional stability / identical fabric sides | 800 |

| |

GW 123-900 L5 | Good dimensional stability / identical fabric sides | 900 |

| |

GW 123-910 L5H1 | Grid structure / identical product sides | 910 |

| |

GW 123-960 L5 | Good dimensional stability / identical fabric sides | 960 |

| BIDIRECTIONAL | |||

| |

GW 223-470 L5 | Good dimensional stability / identical fabric sides | 470 |

| |

GW 223-725 H1 | Grid structure / different fabric sides | 725 |

| UNIDIRECTIONAL CHAIN | |||

| |

GW° 323-235 H1-60 | Grid structure / identical fabric sides / 60° weft angle | 235 |

| |

GW 323-860 L5H1 | Grid structure / identical product sides | 860 |

| |

GWR 323-1020 L5 | Good dimensional stability / identical fabric sides | 1020 |

| UNIDIRECTIONAL SHOT | |||

| THERMOPLASTIC APPLICATIONS | |||

|---|---|---|---|

| GEWEBETYPE | DIRECT SIZING | SURFACE DIMENSIONS g/m² | |

| |

GW 173-600K2 | preferably for the reinforcement of polypropylene | 600 |

| |

GW 176-600K2 | preferably for the reinforcement of polyamide | 600 |

GSO MultiFibre®

GSO MultiFiber® is a variable fabric construction made from hybrid fibers with different characteristics. The symbiosis of the preferred material properties between thermoplastic matrix and reinforcing fibers is particularly suitable for compression molding and injection molding processes.

The hybrid fibers used have a fineness of 1870 tex in a fiber mass proportion of 40 % matrix fiber and 60 % reinforcement fiber.

Properties

Variable fabric constructions:

Bidirectional / unidirectional basis weight orientation

Various basis weights

A wide variety of binding types

Raw material widths up to 410 cm

Cut or uncut, solid or reinforced selvedge

Customized roll lengths

No corrosion

High design freedom, with corresponding strength and rigidity

Markets

Tank and pipeline construction

Aerospace

Vehicle and lightweight construction

Your contact request

By sending your message, you agree to the processing of your data in accordance with our privacy policy. You can revoke this consent at any time.

| GEWEBETYPE | THERMOPLASTIC MATRIX | FIBER CONTENT (%) | SURFACE DIMENSION | |

|---|---|---|---|---|

| MATRIXFIBER | REINFORCING FIBER | g/m² | ||

| GWM 134-600K2 | Polypropylene | 40 | 60 | 600 |

| GWM 134-750/1K2 | Polypropylene | 40 | 60 | 750 |

| GWM 134-980K2 | Polypropylene | 40 | 60 | 980 |

| GWM 134-1485K2 | Polypropylene | 40 | 60 | 1485 |

Commission weaving services

Properties

Variable fabric constructions:

Bidirectional / unidirectional basis weight orientation

Various basis weights

A wide variety of binding types

Raw material widths up to 410 cm

Cut or uncut, solid or reinforced selvedge

Customized roll lengths

No corrosion

High design freedom, with corresponding strength and rigidity

Markets

Aerospace

Ballistics

Vehicle and lightweight construction

Tank and pipeline construction

Your contact request

By sending your message, you agree to the processing of your data in accordance with our privacy policy. You can revoke this consent at any time.

| Type* | Basic yarn | Thread diameter in mm | Tensile strength in N |

|---|---|---|---|

| Hand sewing thread | |||

| HN 80 | EC9-136x5 | 0,8 | > 350 |

| HN 100 | EC9-136x9 | 1,0 | > 610 |

| HN 100 V4A | EC13-136x9 + V4A | 1,0 | > 610 |

| * other types on request | |||